DynoChem®

Summary

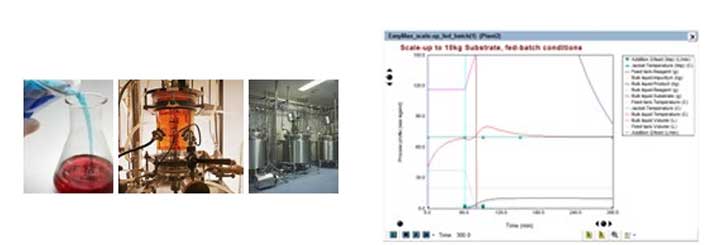

DynoChem®software is an easy-to-use system that helps chemists and engineers develop processes faster and scale them up successfully. It is used globally by 9 of the top 10 pharmaceutical companies, 5 of the top 7 agrochemical companies and leading contract research and manufacturing companies. DynoChem has been successfully applied to hundreds of API reaction steps, work up and isolation stages.

Application Areas

- Laboratory scale reaction optimization

- Right-first-time scale-up of new API reaction steps to multi-purpose reactors

- Flow chemistry initiatives

- Predictive scale-up of workup and isolation steps

- Solvent & anti-solvent selection for crystallization

- Mixing & Heat Transfer Calculations

- VLE & VLLE Calculations

- Continuous improvement of mature processes

- Limited time, data, material and resources for making good process development and scale-up decisions

- Continued re-invention of the wheel, for lack of software tools that are fit for purpose

- Implementation of QbD methodologies

- Exploration of flow chemistry options and continuous processes in general

- Originally developed in industry for use by both chemists and engineers

- No need for users to write, read or solve complex equations

- Mechanistic approach based on classical chemical engineering and physical organic chemistry leads to real process understanding

- Simple Microsoft Excel® model-building interface is familiar to new users and makes it easy to import your data

- Facilitates sharing of process knowledge between disciplines, groups, sites and phases of development

- Wide range of ready-to-edit template models for reactions, work-up and isolation operations, including extraction, solvent exchange, crystallization, filtration and drying

- Equipment-specific, ready-to-edit template models for laboratory and plant reactors

- Extensive Library of Physical Properties data

- Expert project support and training from experienced, PhD qualified chemists and engineers

- Regular community webinars from industrial users and thought leaders

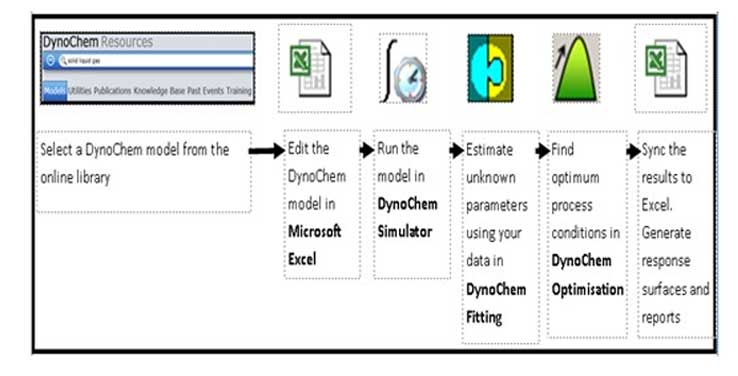

The DynoChem Resources online library contains more than 200 templates and tools for process characterization, simulation, optimization and scale-up, based on first principles of chemical engineering and physical organic chemistry. These models (e.g. for chemical reactions, distillation, extraction, crystallization, filtration and drying) have evolved in more than a decade supporting chemists and engineers worldwide, making and isolating pharmaceutical active ingredients. All of the tools as well as many others that users have developed themselves, are supported by the same flexible DynoChem platform and workflow shown below. This platform can and will be applied to an ever broadening range of applications, anywhere that better understanding of a mass, mole, energy or particle number balance helps process development, scale-up or product performance.

DynoChem makes it easy to include data from your experiments in a model and thereby characterize the unique kinetics or other properties of your proprietary system. You do not need to write, read or solve the complex mass, mole, energy and other balances that describe your system. DynoChem sets up and solves these equations for you, so that you can concentrate on problem-solving. Power Users may add their own custom equations to the system.

Customer success stories

About Scale-up Systems

Scale-up Systems Ltd. (www.scale-up.com) is the owner and developer of DynoChem®. Scale-up Systems supports customers in increasing productivity in R&D and Manufacturing by the adoption of appropriate technologies, enabling collaboration across traditional boundaries and embracing Quality by Design. The company has been operating since 1994 and subsidiaries include its North American distributor, Scale-up Systems Inc., its Indian distributor, Scale-up Systems India Pvt. Ltd and its Asia-Pacific distributor Scale-up Systems (HK) Co., Ltd.